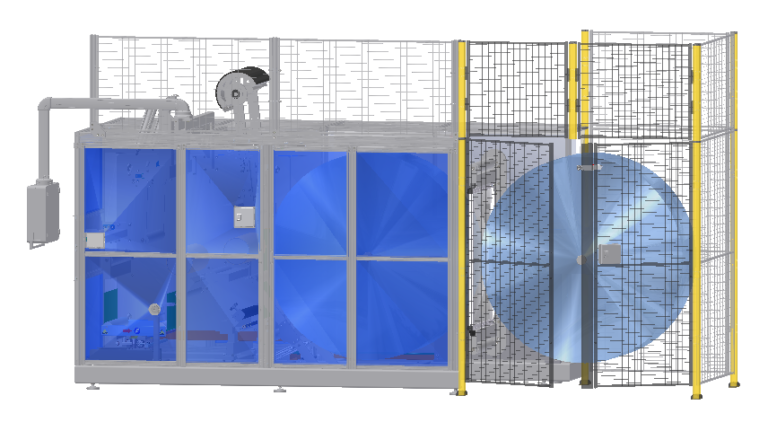

TCW-600 is an innovative machine for continuous winding of webs up to the 500 mm width coming out for instance from extruders.

Continuous winding is assured by the turret with two changing mandrels. Each arm of the turret is bearing the winding mandrel. As soon as one side is filled, the turret turns around the central axis smoothly and finished roll of web is exchanged by the empty mandrel. The automatic precise cross cut of web is executed during the same time.

Drives and electronic control are in standard execution built from components of the SIEMENS company (PLC CPU 1510SP F-1 PN, Simatic S120) assuring outstanding parameters and accuracy.More…

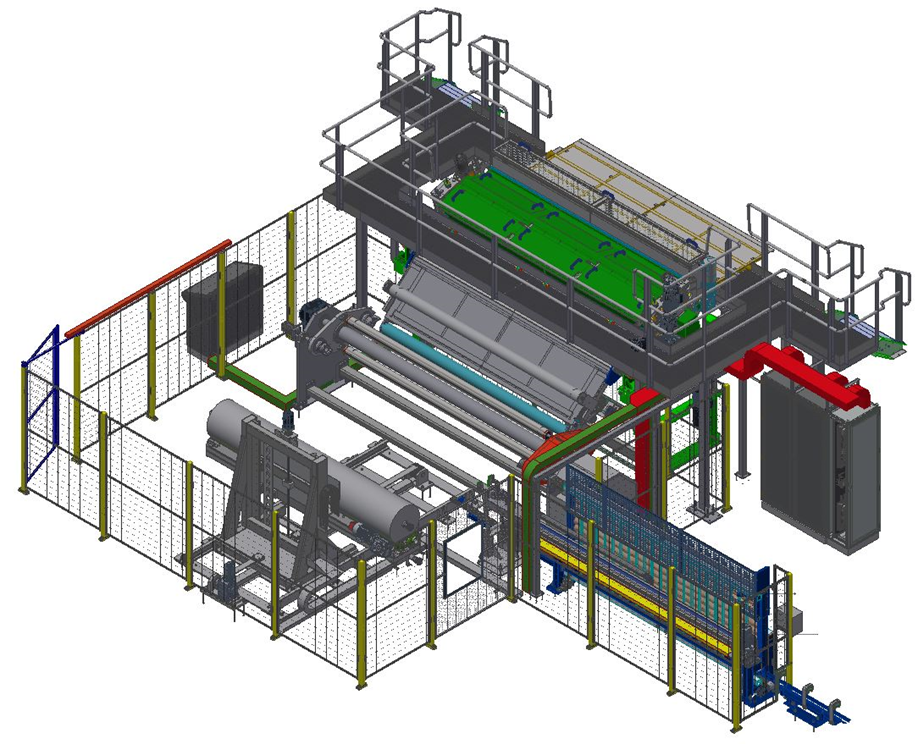

This machine is designed for winding mainly woven multiaxial mats made of such materials as glass, aramid, carbon fibres etc. Thanks to the wide possibilities of setting the winding parameters, it is possible to effect winding in the desired quality from a wide range of materials. By a suitable combination of central and surface winding and contact pressure, large diameter windings can be produced while maintaining their good structure. The combination of a sensitive dancer and a sufficiently strong compensator allows large winding forces to be used even for more sensitive materials and to produce very compact windings. At the same time, the sufficient sizing of the drives also makes it possible to work with robust materials by using considerable winding forces. If required, the winding machine can also be used for simple circumferential winding without the need to handle a separate winding shaft. More…

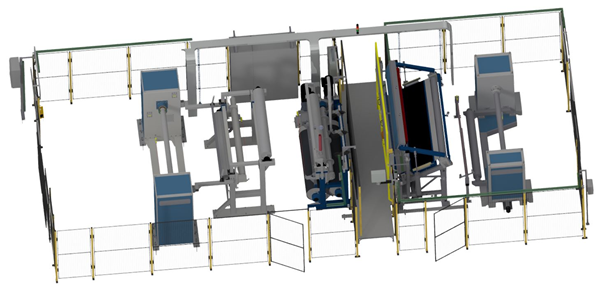

The forming rewinder is designed to rewind a wide range of materials, from glass mesh and non-woven textiles to high-tech composite materials and nanomaterials. It has been developed for easy incorporation into a plethora of technologies according to the requirements of the manufacturing industry, such as printing, lamination or the application of additional layers. The control system and software of the rewinder is based on the latest Siemens technologies and is ready to be integrated into higher-level control systems. The safety concept respects all relevant standards and creates maximum safe working conditions for operation and maintenance. More…

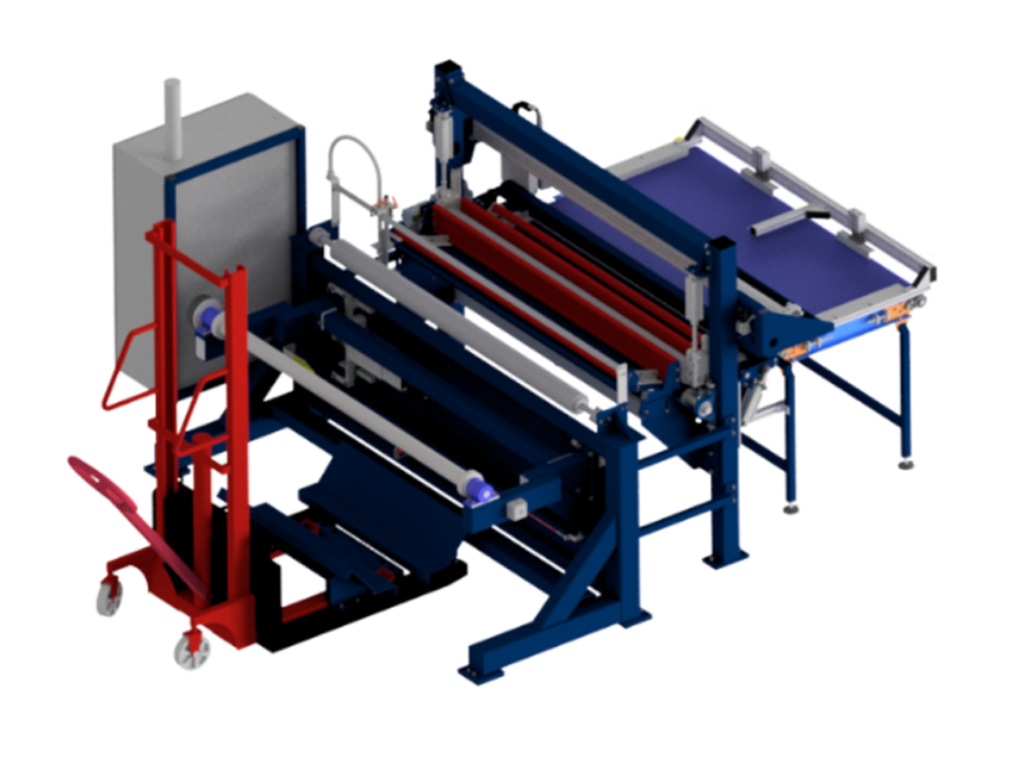

The universal rewinder is designed to work at high production speeds and to handle large bale diameters up to 2.4m. The rewinder can rewind a wide range of materials, from fiberglass matting and fiberglass mesh and non-woven to high-tech materials. The rewinder is used for controlled rewinding, material inspection, cross-cutting, slitting, thermal and pressure bonding of fiberglass mats or other materials. The rewinder and its main parts are often placed as a separate machine next to other production technologies, for example, glass mats. Most often, the rewinder is used as an inspection machine for the continuous winding of glass mats, where rolls of material with defects can be very easily repaired and thus further rolls of good quality material can be obtained. More…

The CSM winder is a reversing winder for continuous winding of a mat made of chopped glass fibres and is located at the end of the CSM (chopped strand mat) line. The winder can be designed according to your requirements – from a basic winder layout to a fully automatic winder layout including a roll handling section and winding shaft puller.

The CSM winder is designed to work with a wide range of mats from the thinnest to the thickest, with both powder and emulsion binders. The machine can be equipped with any functions such as: ironing for more compact windings, edge trimming with automatic introduction into the suction, automatic capture of the start on the tube without adhesive, fully automatic mat feed at the start-up with low-quality mat, double longitudinal slitter for changes on the fly, cross-cutting with sampling possibility, roll and winding shaft handling.

As the CSM automatic winder is always tailored to your specific needs, we are happy to discuss all production parameters and requirements with you. More…

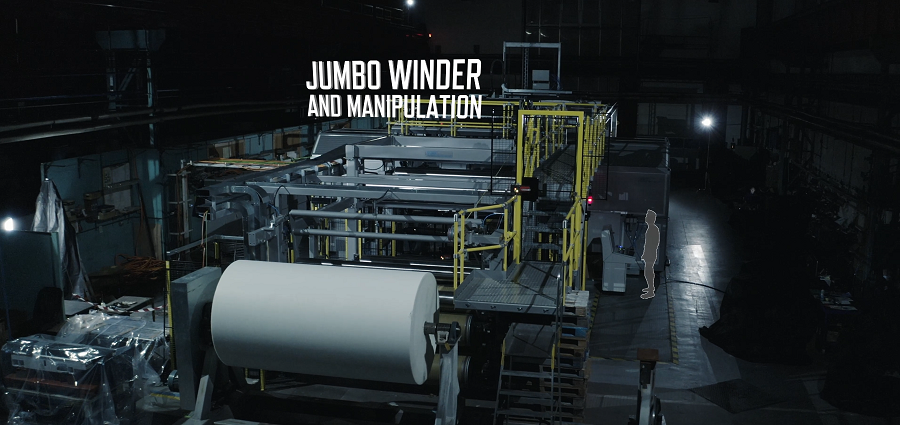

Both the winder and the Jumbo winder are used for continuous controlled winding, inspection, cross and longitudinal cutting of fibreglass mats or other materials.The winder and its parts are placed behind the glass mat manufacturing technology. The winding machine can be designed according to the individual requirements of our customers – from basic equipment to a fully automatic layout, which can include sections for roll and shaft handling as well as packaging, shaft, up to the wrapping line of the final product.The material mat is wound on paper tubes of different diameters. The most common diameters are 6″, 8″10″ and 12″.For continuous winding, it is equipped with two spindles that automatically change when the winding is complete and the mat is smoothly transferred from one spindle to the other. More…

The DST 371 winder is used for continuous winding of glass or basalt fibres. The fibres are wound in a saddle or trapezoidal shape on a plastic or paper tube. For continuous winding, it is equipped with two spindles that automatically change when the winding is completed, while the fibres are transferred from one drum to the other. A rotating wing, which moves over the winding drum, is used to distribute the fibre to the bobbin. The DST 371 is designed to operate in non-stop operation in heavy soiling conditions. The machine can wind 1 – 3 windings simultaneously on a single winding drum. More…

The DST 375 winding machine is used for continuous winding of glass or basalt fibres. The fibres are wound in a saddle or trapezoidal shape on a plastic or paper tube. For continuous winding, it is equipped with two spindles that automatically change when the winding is completed, while the fibres are transferred from one drum to the other. A rotating wing, which moves over the winding drum, is used to distribute the fibre to the bobbin. The DST 375 is designed to operate in non-stop operation in heavy soiling conditions. One or two windings can be wound simultaneously on one machine and on one winding drum. More…

The group of texturizing machines is used for air texturizing glass fibre or a mixture of fibres (glass / Kevlar) in yarns up to a maximum tex of 9600. The material to be texturized is gradually wound on a drum by means of a winding machine. More…

Our cross-cutting unwinding machine is used to format rolls of material such as paper wallpaper or felt into rectangles of almost any length. It is designed to ensure precise cutting of the material and its subsequent picking into the desired position or its transfer to the next processing step with maximum ease of operation. More…

The HCR 1 rewinding machine is designed and manufactured for the rewinding of textile fibre for rope production. The machine enables the material to be rewound from the cross bobbin onto the winding spindle of the skein, its subsequent heat treatment and its rewinding onto the bobbin.

In the first step, the machine allows the material to be rewound from the cross bobbin onto the winding spindle of the skein. The wound material is removed from the spindle and its heat treatment is carried out to shrink the material. In a subsequent step, the material is threaded onto the smaller unwinding spindle of the skein from which it is subsequently unwound and cross wound back onto the bobbin.

For both winding directions, an accumulator is used to prevent damage to the equipment in the event of a jam / kink of the fibre. Both winding directions contain end-of-material detection and the machine stops if end-of-material is detected. More…

The automatic rewinding machine is used for fully automatic rewinding of large rolls – large batches into smaller rolls, cutting off the wound part and sealing the free end. A pre-set code is printed on the tube. The length of the grid in the roll is determined by the technological instructions for the given type of construction grid. The formatting is automatic, the operator only adds the large batches of grids, the tubes to the tray and refills the cartridges of printers, friction stacker and glue application. More…