The automatic rewinding machine is used for fully automatic rewinding of large rolls – large batches into smaller rolls, cutting off the wound part and sealing the free end. A pre-set code is printed on the tube. The length of the grid in the roll is determined by the technological instructions for the given type of construction grid. The formatting is automatic, the operator only adds the large batches of grids, the tubes to the tray and refills the cartridges of printers, friction stacker and glue application.

Most important features:

– Fully automatic rewinding machine for glass mats – mostly leno

– Flexible adaptation to a wide range of products using hmi recipes

– Smooth unwinding control with a wide range of diameters, inertia and cross-cutting

– Adjustable rewind characteristics

– Integrated, certified length measurement

– Automatic tube insertion with hot melt glue application

– Option to wind on the tube without glue

– Tubeless winding directly onto the spreading mandrel

– Automatic handling of output rolls

– Possibility of adding a wrapping line

– Edge guiding system

– Automatic insertion of leaflets under the last layer of leno or under the shrink film in the wrapper

– Automatic fixation of the end of the roll either with two adhesive tapes on the edges of the roll or in the middle with a sticker with printed product information

– Adjustable slow down/stop function at the end of a large batch

– Sophisticated hmi interface enabling to adjust machine behaviour and to monitor current parameters and statistical data

– Remote access

– Integrated quality and production control functions

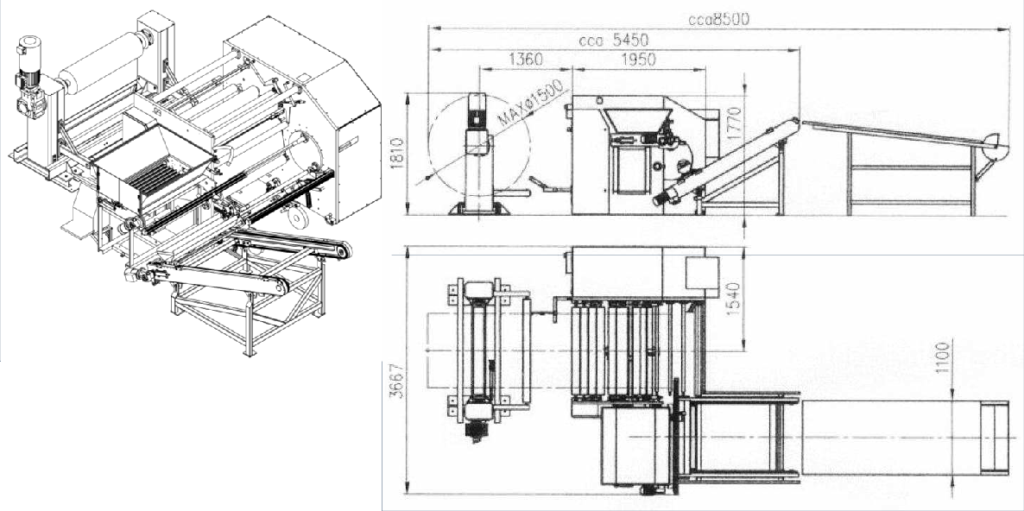

Technical parameters:

Grid width | 1 100 mm, 1 000 mm, 965 mm |

Grid weight span | 125 – 340 g/m2 |

Unwinding shaft diameter | Customer supplied (square end 50 x 50 mm) |

Max. unwinding diameter | 1 600 mm |

Max. weight of large batch to be unwound | 1000 kg |

Diameter of rewind tube | 49 mm, 3“ |

Max. rewinding diameter of winding | 300 mm |

Max. weight of rewinded large batch | 20 kg |