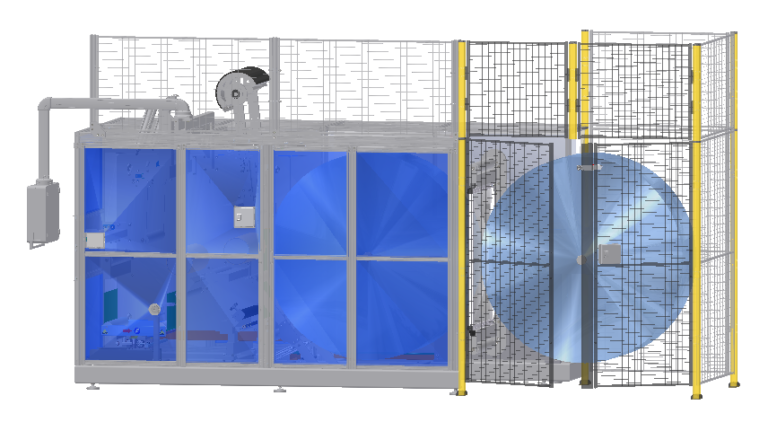

TCW-600 is an innovative machine for continuous winding of webs up to the 500 mm width coming out for instance from extruders.

Continuous winding is assured by the turret with two changing mandrels. Each arm of the turret is bearing the winding mandrel. As soon as one side is filled, the turret turns around the central axis smoothly and finished roll of web is exchanged by the empty mandrel. The automatic precise cross cut of web is executed during the same time.

Drives and electronic control are in standard execution built from components of the SIEMENS company (PLC CPU 1510SP F-1 PN, Simatic S120) assuring outstanding parameters and accuracy.More…

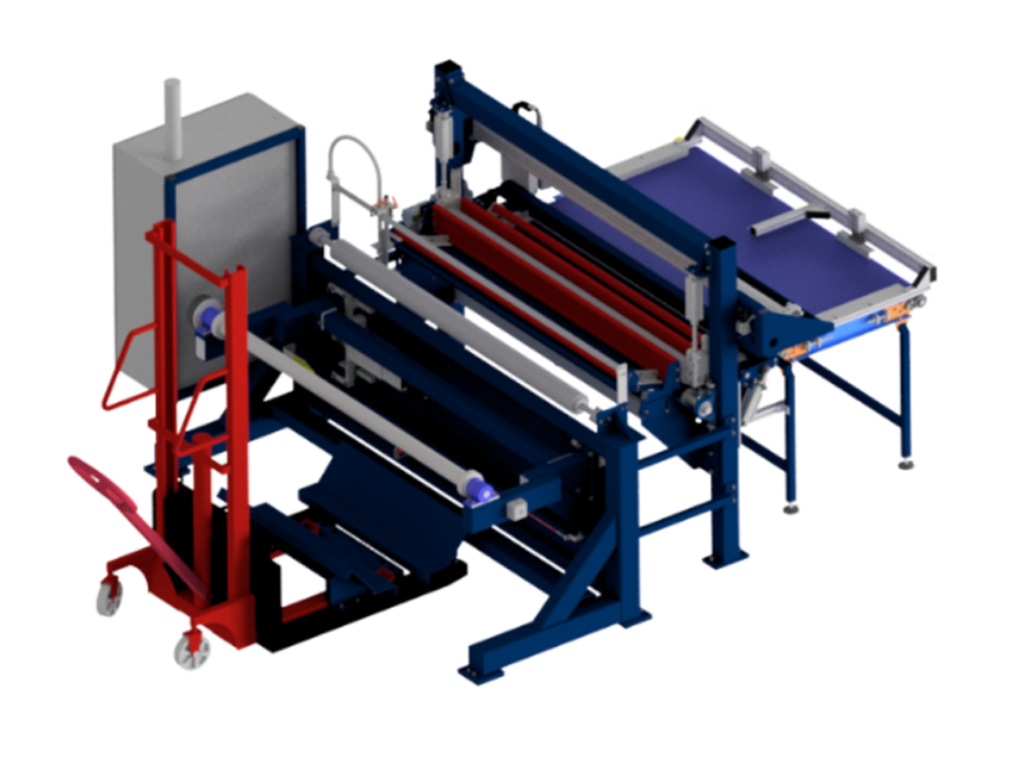

Our cross-cutting unwinding machine is used to format rolls of material such as paper wallpaper or felt into rectangles of almost any length. It is designed to ensure precise cutting of the material and its subsequent picking into the desired position or its transfer to the next processing step with maximum ease of operation. More…

The HCR 1 rewinding machine is designed and manufactured for the rewinding of textile fibre for rope production. The machine enables the material to be rewound from the cross bobbin onto the winding spindle of the skein, its subsequent heat treatment and its rewinding onto the bobbin.

In the first step, the machine allows the material to be rewound from the cross bobbin onto the winding spindle of the skein. The wound material is removed from the spindle and its heat treatment is carried out to shrink the material. In a subsequent step, the material is threaded onto the smaller unwinding spindle of the skein from which it is subsequently unwound and cross wound back onto the bobbin.

For both winding directions, an accumulator is used to prevent damage to the equipment in the event of a jam / kink of the fibre. Both winding directions contain end-of-material detection and the machine stops if end-of-material is detected. More…